3D Printing

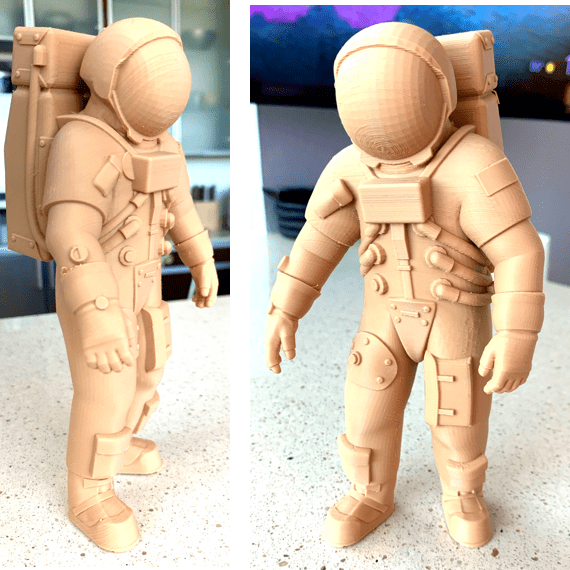

Astronaut

This was a complex print that required multiple supports. The model needed to be printed at angle to prevent any loss of detail in the hands.

Print Details: .1mm layer height resolution Filament: 1.75mm Matterhackers Wood Filament Print time: 12 hrs 37 min Print temp: 210 degrees celsius Bed temp: 65 degrees celsius Height: 180mm Supports: Yes

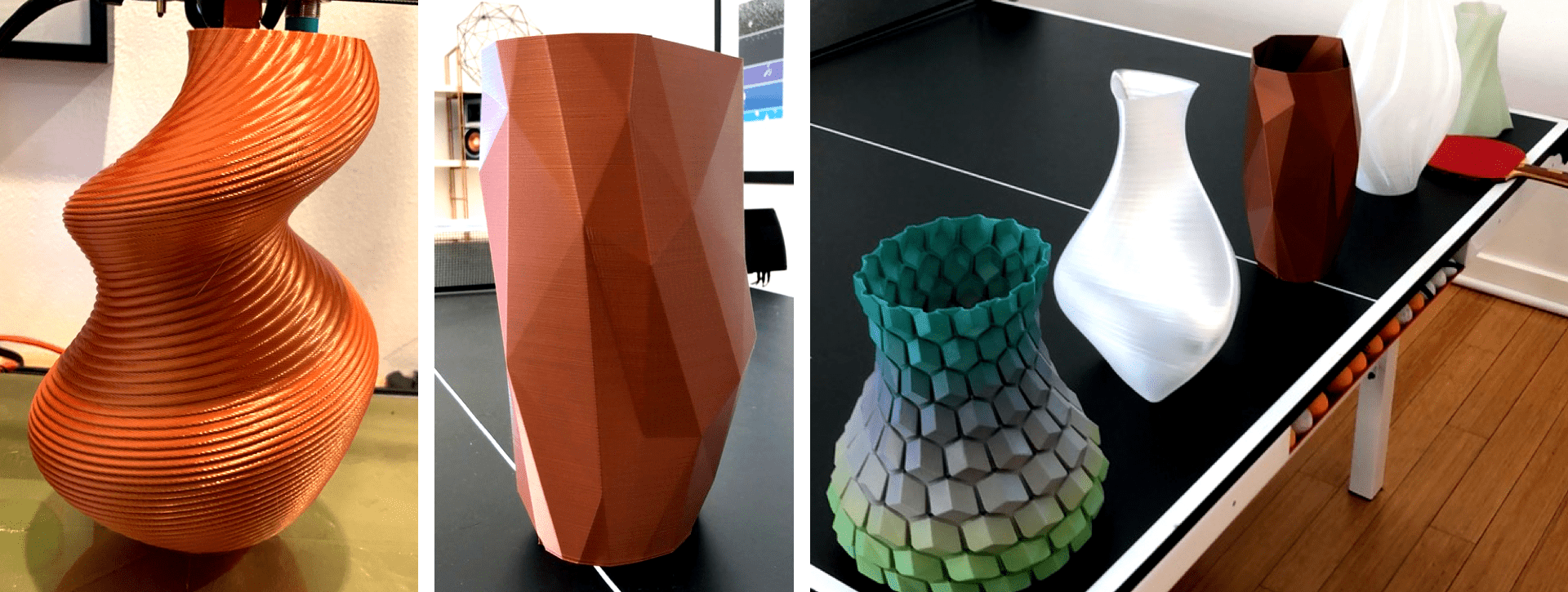

Copper Vase

Designing vases has become one of my favorite past times. By designing a few patterns and wrapping them around a model in Fusion 360, it yields unique and stunning results.

Print Details: .1mm layer height resolution Filament: 1.75mm Matterhackers Copper Filament Print time: 20 hrs 54 min Print temp: 210 degrees celsius Bed temp: 65 degrees celsius Supports: No

Buddha

This buddha model was a great opportunity to test the printers detail. By printing it in wood, it allows me to sand and stain the model, which will take on a natural wood grain.

Print Details: .1mm layer height resolution Filament: 1.75mm Matterhackers Wood Filament Print time: 24 hrs 11 min Print temp: 210 degrees celsius Bed temp: 65 degrees celsius Supports: Yes

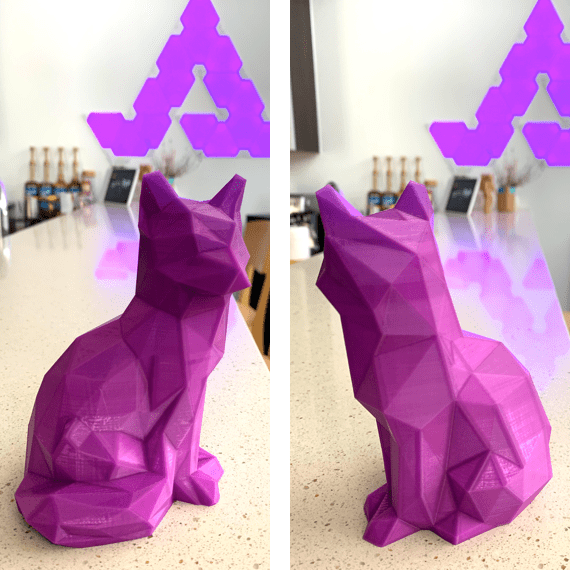

Polygon Fox

This model was printed with a temperature sensitive filament that will change colors from purple to pink when exposed to cold or heat.

Print Details: .1mm layer height resolution Filament: 1.75mm Matterhackers Wood Filament Print time: 8 hrs 58 min Print temp: 210 degrees celsius Bed temp: 65 degrees celsius Supports: No

Heat Station

With my new love for 3D Printing, I quickly realized my prints could be better with some modifications to the printer. In modifying the printer, I needed to learn how to solder.

By allowing myself to learn to solder, it opened up a world of possibilities for modifying the printer. Upgrading everything from hot ends to replacing power supplies, I enjoy tinkering and making things perform at their best.

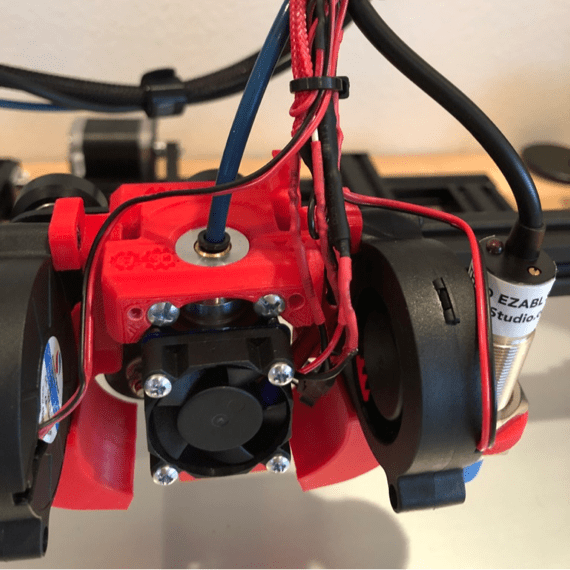

Upgraded Hot End

To print flexible and extra hard or abrasive materials, I needed to upgrade to an all-metal hot end.

By printing the upgraded parts, installing silent fans, an auto-leveling sensor, and capricorn bowden tube, this allowed me to print with abrasive and very flexible filaments with a quality finish.

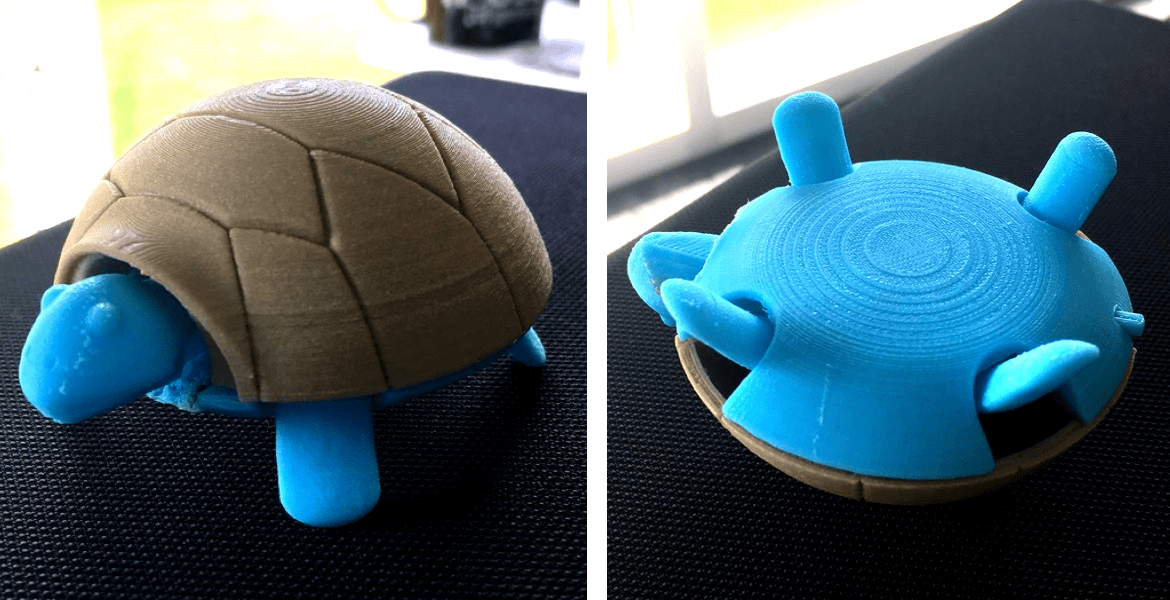

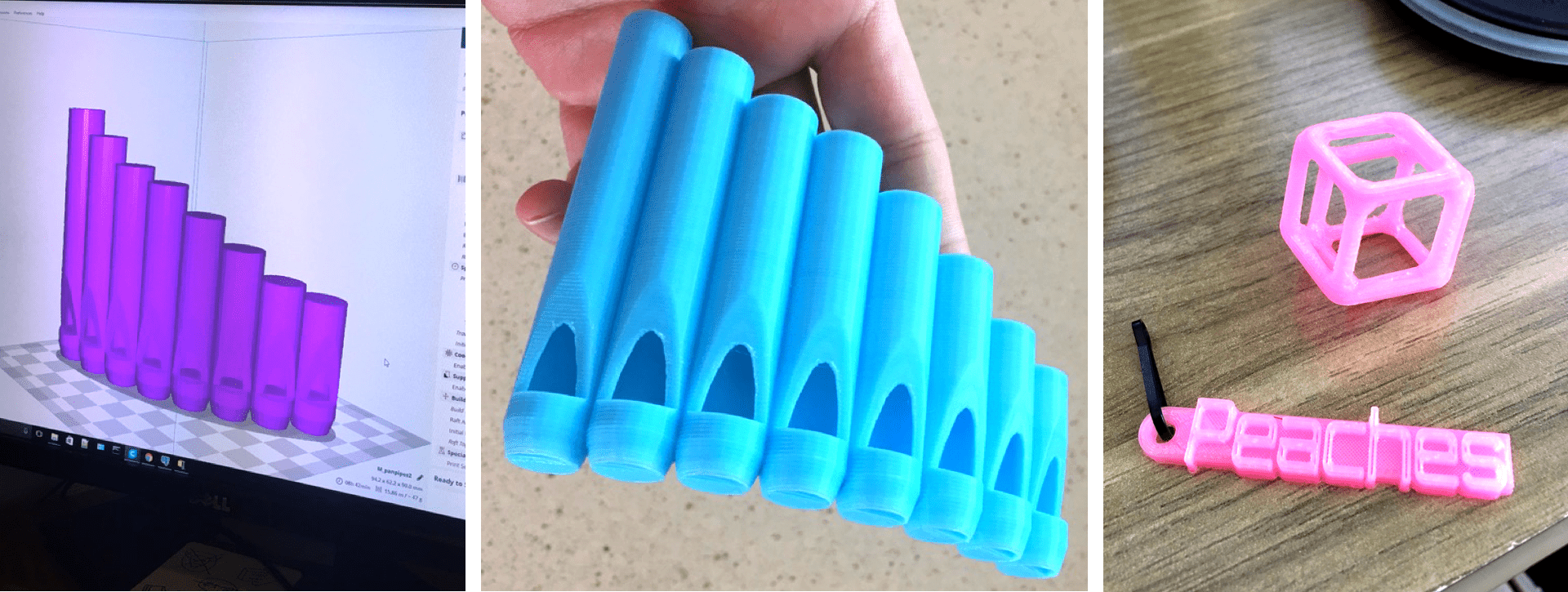

Succulent Planter

Being able to print your own pots for plants has given me an appreciation for some much needed desk flair.

With a drip tray, wooden legs, and a complimentary dinosaur phone holder, this succulent enjoys a spot on my desk.

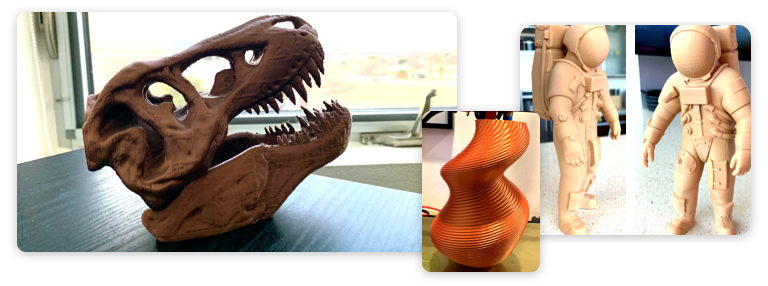

T-Rex Skull

Owning multiple 3D Printers has given me the ability to print some of my favorite childhood dinosaur models.

This was a difficult print and took several attempts to get the settings right. It printed in two parts, the jaw separating from the top half. No supports were used for this snaggly dino.